NO.EL. Prestretched is an effective hand stretch film which can be used to wrap a wide variety of goods.

It is already pre-stretched and so needs less tension and is easier to apply.

Crucially it is approximately half the thickness of a standard stretch wrap film.

Advances in raw materials and technology have enabled us to develop lighter films which retain the strength and performance of previous products. As a 7 micron pre-stretched product, less film by weight is required to wrap a given load with NO.EL.

Prestretched which means that ultimately there is less packaging to dispose of.

Additionally, as fewer film deliveries are required there is a reduction in the associated delivery vehicle emissions.

NO.EL. Prestretched is 100% recyclable and can be processed through industrial film recycling facilities

If you currently wrap 100,000 pallets a year using a 20 micron film you will be using approximately 60,000 kilograms* of stretch wrap per annum. Wrapping the same 100,000 pallets with NO.EL. Prestretched means that you would use only 13,500 kilograms of stretch wrap.

Therefore, over a year you would have 36,500 kilos less to dispose of

-Example-

An existing customer who is located 200 miles from the supplier’s site and requires 9 deliveries of stretch film per annum.

In a standard pallet of 360 Hand Reels we have 7/8.000 mts. of Wrap Film in 20 microns, in a NO.EL.

Prestretched pallet we have 20/21.000 mts. The lorry delivering these loads runs at 10 miles to 4.5 litres of diesel which means that the carbon emissions for this one delivery point each year is 2.170 kg CO2 equivalent to 395 kgs carbon.

(*Source: CO2 calculator, National Energy Efficiency website).

If we had been transporting NO.EL. Prestretched and had been able to deliver the same meterage in just three deliveries.

This would have saved 1.446 kgs CO2 equivalent to 394 kgs carbon.

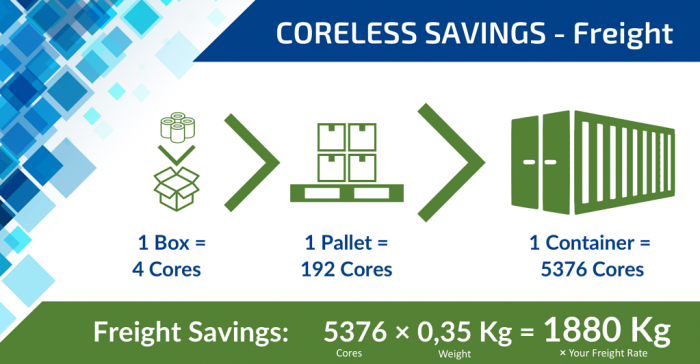

Introducing “ Noel Coreless “, Stretch Wrap Film manufactured by No.El.

Technology without Carboard Core A greener solution to stretch wrapping needs. All the performance of a standard stretch film but less waste by virtue of the fact that it is coreless. Highly versatile NO.EL. Coreless can be used to wrap a wide variety of loads.

No core means less waste to dispose of saving time, money and effort.

Helps to meet the requirements of the Packaging Waste Regulations

NO.EL. Coreless is supplied with special dispensers to make film application as effortless as possible.